The DTF (Direct to Film) printing technology is increasingly asserting its position in the printing industry thanks to its flexibility and superior quality. But have you ever been curious about the process of creating a finished DTF product? This article will decode each step in the DTF printing process, helping you gain a better understanding of this modern technology.

Step 1: Design and Print File Preparation

Every printing process begins with preparing the design file. For DTF printing, you need to use professional graphic design software such as Adobe Illustrator, CorelDRAW, or Photoshop, or other graphic programs.

File Format:

- The design file should be in vector formats (AI, EPS, PDF) or high-quality (PNG) to ensure sharp images during printing.

Color Mode:

- Use the CMYK (Cyan, Magenta, Yellow, Black) color model to achieve the highest color accuracy. Alternatively, you can also use the RGB color model after finishing the design, and the printing software will automatically convert it to the CMYK system.

Print File Size and Resolution:

- Make sure your size fits the area you want to print on the garment or product. Regarding print resolution, you should set it to 300 ppi (pixels/inch) for PNG format images. This ensures clear and sharp images when printing.

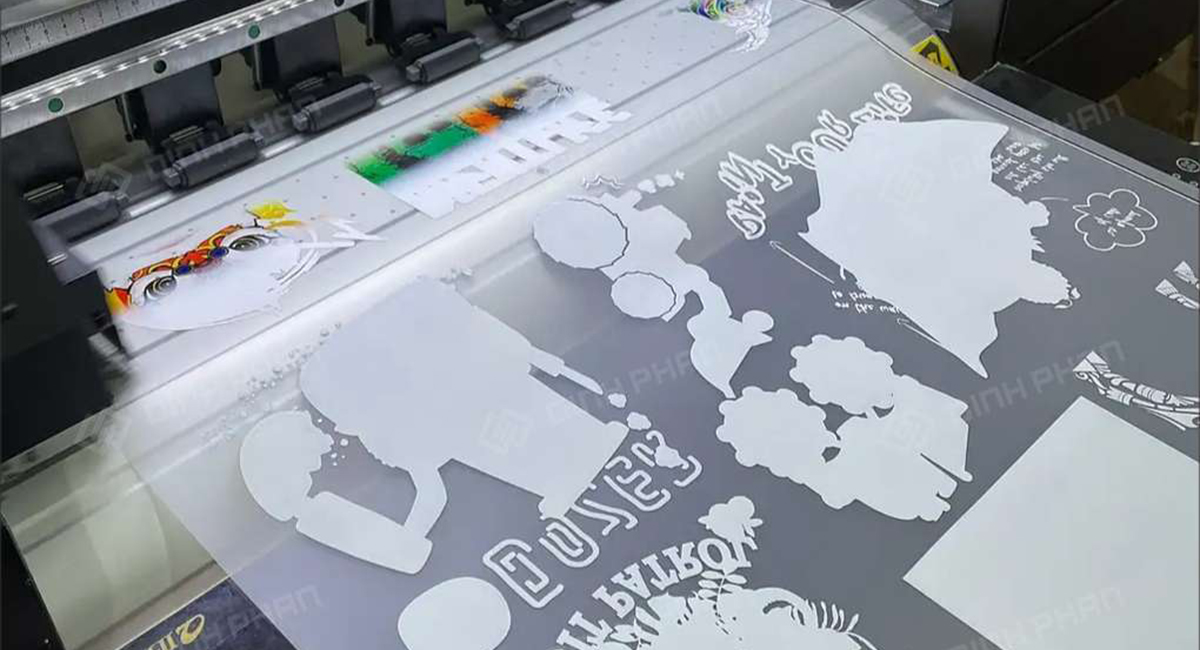

Step 2: Printing the Image onto DTF Film

Once the file has been prepared, the image will be printed onto a special type of film called DTF film.

Specialized Printer:

- The DTF printer uses DTF ink, which includes the basic colors (CMYK) and white ink (White).

Reverse Printing Process:

The printer will print the color layer first, and then print the white layer on top. This ensures that during heat pressing, the color layer will be on top, visible to the viewer. All Rip software has functions that allow you to set which color is printed first and which is printed last.

Step 3: Applying Hotmelt Powder and Curing

Immediately after printing, while the ink is still wet, the film sheet is coated with a layer of hotmelt adhesive powder.

Powder Application:

- The adhesive powder is sprinkled evenly over the entire printed image. The excess powder is removed, leaving only the layer of adhesive adhering to the ink.

Curing/Drying:

- The film sheet is then placed into a dedicated dryer or oven to allow the powder to melt and firmly adhere to the ink. This process helps the printed image form a flexible layer, ready to be pressed onto the fabric.

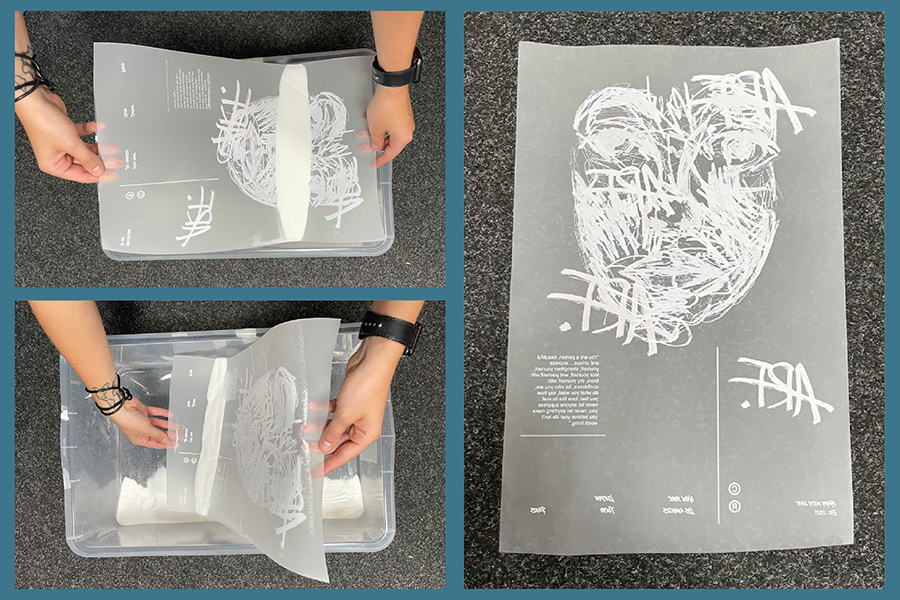

Step 4: Heat Pressing onto the Garment

This is the final stage to complete the product.

Preparation:

- Place the T-shirt (or the material to be printed on) onto the heat press machine. Place the DTF film sheet onto the shirt so that the printed image side is in contact with the fabric.

First Press:

- Press at a specific temperature and time (usually around 150-160°C for 10-15 seconds). The adhesive layer will melt and firmly bond the image to the shirt.

Peeling the Film:

- After the first press, wait until the film has completely cooled down, then gently peel off the film layer.

Second Press (Re-press):

- Press again (you can place a layer of parchment paper on top) to make the print adhere more securely and achieve a nicer finish/sheen.

Outstanding Advantages of the DTF Printing Process

- Versatility Across All Materials: This is the “highlight” of DTF. You can print on cotton, polyester, blended fabrics, silk, leather, and many other types of materials without needing to change the printing process.

- Simple and Time-Saving Process: DTF does not require a fabric pre-treatment step, allowing you to bypass a costly process and save time and labor.

- High Durability: DTF prints feature high resolution, along with superior durability, being water-resistant, UV-resistant, and resisting peeling after multiple washes. The thin adhesive layer helps the print adhere firmly to the fabric surface.

- Cost-Effectiveness: The initial investment cost for DTF machinery and supplies is lower compared to DTG (Direct-to-Garment). Furthermore, this technology allows you to print multiple designs onto the film in bulk, then press them onto shirts gradually, optimizing the production process.

With a simple yet highly effective process, DTF printing technology has been and continues to be the leading choice for modern printing businesses, especially in the field of personalized T-shirt production.