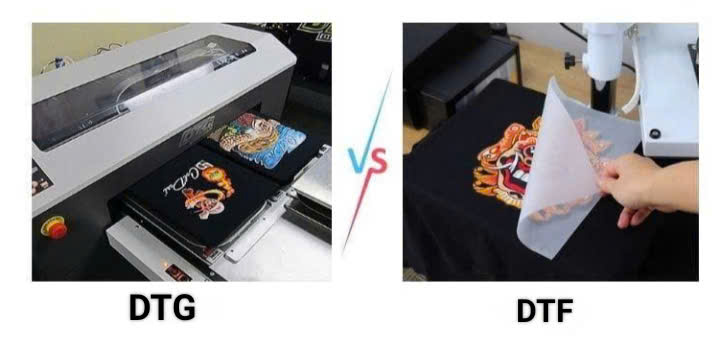

In the highly competitive fashion printing industry, choosing the right printing technology not only determines product quality but also directly impacts your profit margins. The two technologies most frequently mentioned today are DTG (Direct-to-Garment) printing and DTF (Direct-to-Film) printing. Both offer modern printing solutions, but without a clear understanding, you can easily make mistakes and waste resources.

This article will serve as a detailed A-to-Z guide, helping you fully grasp the nature, advantages, and disadvantages of each technology, thereby enabling you to make the smartest decision to optimize your business efficiency.

DTG (Direct-to-Garment): The Mark of Sophistication

DTG is a digital printing method applied directly onto the fabric. The ink is sprayed straight into the fabric fibers, where it absorbs deeply and adheres firmly. As a result, the print does not have a stiff or raised feel, providing a soft and natural finish just like the fabric itself.

Outstanding Advantages:

- Image Quality : DTG printing reproduces images with perfect sharpness, detail, and color gradients. The inks are flexibly mixed, allowing you to print detailed portraits or complex designs vividly and realistically.

- Print Feel (Hand-Feel): This is the biggest advantage of DTG printing. Because the ink absorbs into the fabric, the print is very soft, breathable, and does not cause stuffiness or a raised/stiff sensation. This is crucial for premium T-shirt products or children’s clothing, where comfort is the primary factor.

- Unlimited Colors: Using the CMYK and white ink systems, you can create millions of different colors, meeting all design requirements, and allowing printing on dark fabrics.

Disadvantages to Consider:

- Material Limitations: DTG printing works most effectively on 100% cotton fabrics or those with a high cotton content. Printing on polyester, blends, or certain dark fabrics requires a more complex pre-treatment step, which increases both time and cost.

- High Investment and Production Costs: DTG printers and specialized inks have a high price tag. Furthermore, the printing process requires a pre-treatment step, increasing the production cost per item.

- Production Time: Faster than screen printing, but potentially slower than DTF.

DTF (Direct-to-Film) Printing: The Solution of Versatility

DTF printing is an advanced digital printing method that allows images to be printed directly onto a specialized film layer (PET Film). This image layer is then transferred onto the surface of the material using heat and adhesive powder. This process offers many outstanding advantages over traditional printing methods. The final print is transferred from the film to the fabric using a heat press.

Outstanding Advantages:

- Versatility Across All Materials: This is the “highlight” of DTF printing. You can print on cotton, polyester, blends, silk, leather, and many other types of materials without needing to change the printing process.

- Simple Process, Time-Saving: DTF does not require a pre-treatment step for the fabric, allowing you to skip a costly stage, saving time and labor.

- High Durability: DTF prints have high resolution, coupled with superior durability, being water-resistant, UV-resistant, and won’t peel or crack after multiple washes. The thin adhesive layer helps the print stick firmly to the fabric surface.

- Economic Efficiency: The initial investment cost for a DTF printer and supplies is lower than for DTG. Notably, this technology allows you to print multiple images onto a film sheet (gang-sheet) and then press them onto garments gradually, which helps optimize the production process.

Disadvantages to Note:

- Cost per product is usually higher than screen printing when producing extremely large quantities.

- Prints with excessively large sizes can feel stiff and trap heat on the fabric surface.

The Ultimate Guide to Optimal Selection for Your Business

This is the most crucial part, helping you make the right decision based on your business objectives.

When to Choose DTG?

- Premium Product Segment: If you want to build a high-end fashion brand, focusing on fabric quality and comfort, DTG is an irreplaceable choice.

- Small-Batch Production, Print-on-Demand (POD): For orders involving single shirts or small quantities, DTG allows you to create high-quality products without incurring high initial setup costs.

- Complex Designs: If your designs feature many small details and subtle color gradients, DTG printing will render them most completely.

When to Choose DTF?

- Product Diversification: If you want to print on various materials (polyester shirts, uniforms, canvas bags, etc.), DTF is the most flexible and effective choice.

- Large-Volume Production: DTF allows for mass printing onto film, which then only requires heat pressing onto the garment. This process saves time and costs, making it highly suitable for uniform orders or mass production.

- Cost Optimization: DTF has lower initial investment costs, making it easier for small businesses and startups to access.

DTF and DTG printing are not rivals, but rather two complementary solutions. DTG printing offers sophistication, luxury, and excellent image quality, suitable for the premium segment. Meanwhile, DTF printing stands out with its versatility, efficiency, and ability to print on various materials, making it the ideal choice for large-volume and diverse production orders.

A clear understanding and the correct choice of technology will not only help you create quality products but also serve as the key to optimizing your production process and achieving sustainable profit growth.