The T-shirt printing market is a potential gold mine, but to turn this potential into massive profits, you need the right investment decision. The choice between the two leading digital printing technologies – DTF (Direct to Film) and DTG (Direct to Garment) – is not just about selecting print quality; it’s about choosing a profit model for your business.

This article will outline 9 key points, providing a detailed analysis of financial factors, hidden costs, and operational efficiency to help you determine: Which technology will deliver the highest profitability for your business strategy?

I. Profitability from the Perspective of Investment and Operational Costs (Cost Per Print – CPP)

Profitability begins with controlling the cost of production per unit (CPP). The technology that helps lower the CPP will hold the competitive advantage.

1. Equipment Depreciation Cost (CAPEX): DTF Printing Is More Accessible

DTG Printers:

- Industrial DTG printer models (like the Epson F-Series or Brother GTX) often have a significantly higher initial investment cost. This leads to a larger depreciation cost per product, increasing the initial financial burden.

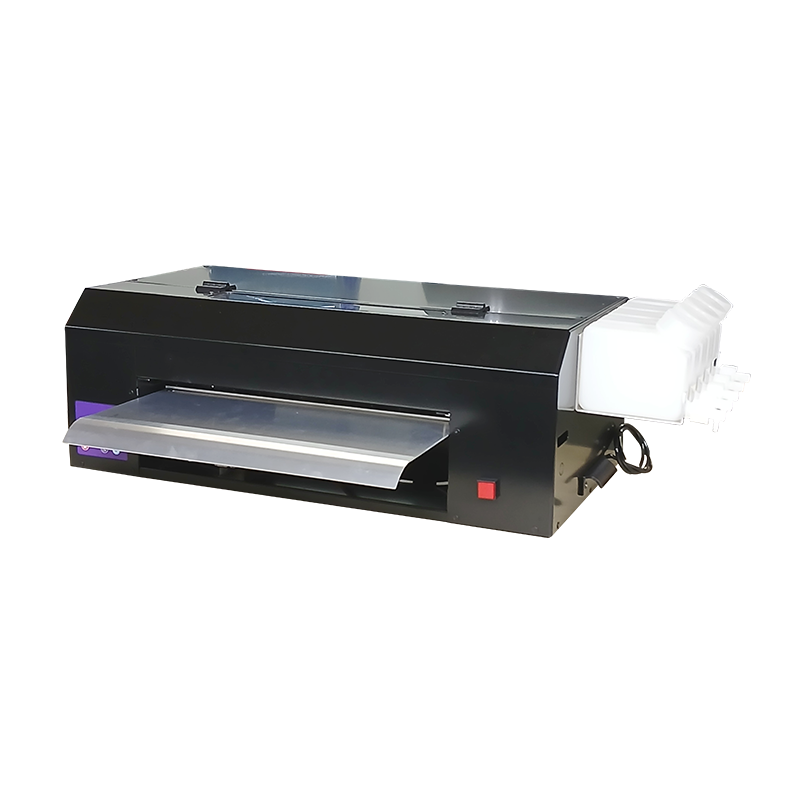

DTF Printers:

- The initial investment cost for a DTF printing system (DTF printer, powder shaker, curing oven) is generally lower, especially for small- and medium-format machines.

Profit Highlight:

- For a tight budget or a startup model, DTF printing helps reduce the depreciation cost per T-shirt in the initial phase, accelerating the Return on Investment (ROI) process.

2. Hidden Maintenance Costs: DTG’s Biggest Risk

DTG:

- The maintenance cost for white ink printheads is the biggest hidden cost, eroding profitability. DTG white ink is prone to sedimentation, leading to a high risk of nozzle clogging, which requires frequent and expensive cleaning and maintenance.

DTF:

- The operational process is simpler, with a lower risk of ink clogging. The associated maintenance costs are lower, and the machine experiences less downtime.

Profit Highlight:

- DTF printing minimizes machine downtime and eliminates expensive repair costs, ensuring a more stable cash flow.

3. White Ink Costs: DTF Printers Save Up to 60%

DTG:

- To ensure vibrant colors and good coverage on dark fabrics, DTG printing requires a large amount of white ink and the mandatory Pre-treatment step (fabric treatment solution). This significantly increases the DTG material cost.

DTF:

- DTF requires only about 40% of the white ink volume compared to DTG to achieve equivalent coverage, and does not require Pre-treatment.

Profit Highlight:

- This is a deciding factor. In high-volume printing, digital transfer printing (DTF) optimizes material costs more effectively than DTG, especially when printing designs that require a white underbase layer.

II. Profitability from the Perspective of Productivity and Market Expansion

The speed and adaptability of the technology determine the scale of revenue and the potential for business expansion.

4. Production Speed: DTF Printing Doubles Productivity/Hour

DTG:

- The printing process is slower due to required additional steps such as pre-treating the fabric, curing the pre-treatment, printing, and drying.

DTF:

- The process is optimized (Print onto Film > Powder Shaking > Heat Press). Businesses can print a batch of film transfers first, and then heat press multiple shirts simultaneously.

Profit Highlight:

- The faster speed of DTF printers helps increase output per hour, allowing the business to accept and complete large-volume orders (Mass Production) quickly, thereby maximizing gross profit.

5. Multi-Material Profitability (Market Expansion)

DTG:

- Works best on 100% Cotton fabric. The target market is limited.

DTF:

- Can print on almost any material: Cotton, Polyester, Blended Fabrics (50/50), Nylon, Leather, etc.

Profit Highlight:

- The flexibility of DTF printing helps businesses expand their customer base to include printing for uniforms, sportswear, windbreakers, bags, hats, etc., creating a diverse and stable revenue stream.

6. Break-Even Point

- Due to lower initial investment costs and optimized CPP, business models utilizing DTF printing technology typically reach the break-even point faster compared to DTG printing shops. This helps investors reduce financial pressure during the initial phase.

III. Profitability from the Perspective of Pricing and Sales Strategy

Although DTF printers win on cost, DTG printing holds an advantage in product pricing.

7. High Premium Profit Margin (DTG’s Strength)

- The print quality is soft, breathable, and aesthetically superior (printed directly into the fabric fibers).

Pricing Strategy:

- DTG printing is suitable for High-End Fashion Brands (Luxury POD). You can price the products very high, generating a large Gross Profit Margin on each shirt.

8. Profitability from Volume (DTF’s Strength)

- Good print quality, high durability, but the print feel can be thicker.

Pricing Strategy:

- DTF printing is suitable for sales strategies based on competitive pricing and high volume (uniforms, event giveaways). Profit comes from optimizing the process and the sheer volume of sales.

9. Optimal Choice for Your Business Model

Choosing DTG

- Profit Goal: Large Profit Margin per product.

- Suitable for: High-end fashion brands, small-volume printing, artistic photos.

- Investment Capital: Requires a higher initial capital.

Choosing DTF

- Profit Goal: Growth profit and Cost Optimization.

- Suitable for: Mass production, uniform printing, multi-material applications.

- Investment Capital: Lower initial investment, lower risk.

Which Technology Fits Your Profit Goals?

There is no single, absolute “best” technique; there is only the technology that is most suitable for your profit model.

If you are building a luxury brand, valuing perceived quality as your core value, choose DTG and accept the higher operational costs.

If your business needs to maximize profit from order volume, diversify printed products, and require a stable operational solution with a low Cost Per Print (CPP), choose a DTF printer.

Do not hesitate to experience them. If you have any questions about the product, from materials to usage, please contact us immediately. We believe that your satisfaction will be the best answer to product quality.