POD Printing Technology market enters 2026 with an unprecedented level of fierce competition. Millions of sellers join every year, but only a very small percentage can maintain sustainable profitability. The factor determining the survival of a POD brand lies not only in design or advertising, but in the quality of the final product, and the core of this quality is the printing technology itself.

Choosing the wrong pod printing technology can lead to products that quickly peel or fade, resulting in a high return rate, destroying selling accounts, and devastating brand reputation. So, what is the best printing technology for POD in 2026?

This article will comprehensively analyze the three main printing technologies currently available: DTG (Direct-to-Garment), DTF (Direct-to-Film), and Thermal Sublimation Printing (Sublimation), thereby helping you make the optimal strategic choice for POD profitability.

POD printing Technology – The Decisive Factor for POD Profitability

In the POD printing Technology business model, everything from design and marketing to the supply chain is important, but the printing stage is the soul of the product. A crisp, durable print that withstands dozens of washes can create loyal customers. Conversely, just one faulty printed product is enough to make a customer leave permanently.

Consequently, thoroughly understanding the pros and cons of each POD printing technology is mandatory if you want to scale and ensure long-term survival.

DTG (Direct-to-Garment) Technology – “The Giant” Facing an Uphill Climb

How does DTG work?

DTG printing operates similarly to a giant office inkjet printer. Water-based inks are sprayed directly onto the fabric surface. For dark fabrics, a layer of Pre-treatment solution is sprayed first to help the white ink adhere better, followed by the printing and curing process.

Undeniable Advantage: The King of Hand Feel

- Excellent Hand Feel: This is the biggest advantage. The ink penetrates deep into the cotton fibers, making the print very soft, with almost no raised or heavy feel. The printed area retains high breathability.

- Detail Reproduction: Perfect for complex designs, gradient effects, and tiny details, delivering the highest premium print quality.

The Achilles’ Heel” of DTG

Despite its superior image quality, DTG faces many challenges in the POD environment which demands speed and flexibility:

- Material Limitations: DTG is optimized for 100% Cotton fabric. When printing on Polyester or blended fabrics, the quality decreases and the cost of Pre-treatment supplies increases significantly.

- Slow Production Speed: The multi-step process (Pre-treatment, drying, printing, drying again) results in a longer turnaround time per product.

- High Maintenance Costs: Water-based DTG ink easily dries and clogs the print heads. The cost of machine maintenance and ink is a major barrier for small-scale POD workshops.

DTF (Direct-to-Film) – The New King Balancing Quality and Cost

How does DTF work?

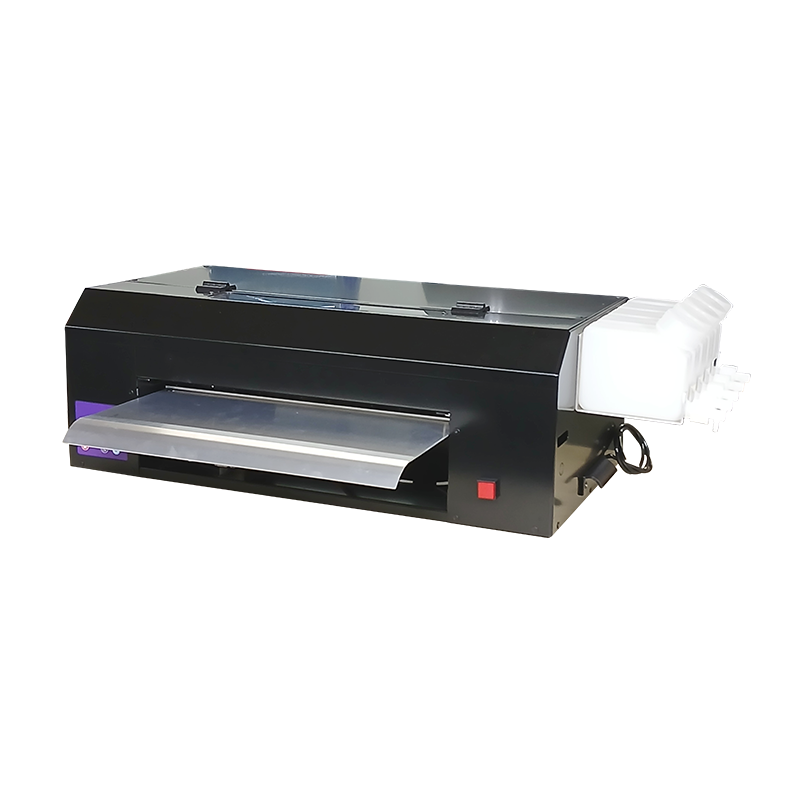

DTF technology is a hybrid heat transfer process that addresses most of DTG’s drawbacks. The process involves four steps:

- Printing white and color ink onto a specialized transfer film.

- Coating the wet print with a layer of hot-melt adhesive powder.

- Curing (heating) the film to melt the adhesive and bond it to the ink.

- Pressing the cured film onto the fabric using a heat press machine.

Advantages That Led DTF to Explode and Dominate POD

DTF is not just an alternative technology; it is an optimized solution for the POD business model:

- Absolute Versatility: This is the game-changer. DTF can print on all types of fabrics and materials (Cotton, Polyester, Nylon, Denim, Leather, Wood,…) and all colors, including dark fabrics, without requiring pre-treatment.

- Superior Mechanical Durability: DTF prints have excellent stretchability, resisting cracks and peeling better than DTG after multiple washes.

- Speed and Cost: The process is faster and uses fewer consumables than DTG. Most importantly, the printed film can be stored and pressed anytime, allowing print shops to optimize mass production.

Drawbacks That Must Be Accepted

- Hand Feel: Because the print is a thin layer of ink and adhesive lying on the fabric surface, it has a slight thickness and a somewhat “plastic” feel compared to DTG.

- Breathability: The breathability of the printed area is slightly reduced; however, newer DTF technologies have significantly improved this aspect.

Thermal Sublimation Printing (Sublimation) – The King of Absolute Durability

How does Sublimation work?

Thermal Sublimation Printing is a chemical process. When exposed to high temperature and pressure, the ink changes from a solid to a gaseous state (sublimates) and deeply penetrates, blending permanently with the fabric fibers or material.

Immortal” Advantages and Major Limitations Advantages

- Eternal Durability: The print will never fade, crack, or peel. It becomes a permanent part of the product.

- All-over-print: Sublimation is the ideal technology for printing across the entire surface of a product.

Major Limitation

This technology MUST use Polyester materials (a minimum of 60%) and light colors. It absolutely cannot print on cotton fabric.

Applications in POD

Sublimation is not a competitor to DTF/DTG for cotton T-shirts, but it is the mandatory and optimal choice for: Sports jerseys, windbreakers, ceramic mugs, phone cases, mousepads, and various other souvenir products.The Race – Strategic Choice for POD Profitability

Strategic Conclusion

- Overall Winner: DTF (The New King): With its flexibility, optimized cost, and enduring quality, DTF is the most balanced choice and the best printing technology for the majority of current mass-market and diverse POD products. It minimizes risks and increases the potential for product expansion (scaling).

- Premium Choice: DTG: If you position your brand in the high-end 100% Cotton T-shirt segment (Premium), selling at a high price and focusing on an absolutely soft hand feel, DTG remains number one.

- Specialized Choice: Sublimation: If your niche market is sportswear or souvenir items, Sublimation is the mandatory choice.

Don’t just follow the trend; thoroughly investigate which technology your POD supplier is using. Switching to a partner with a modern DTF process could be the decisive step to maximize profits and build a successful POD brand in 2026.