The Secret to Perfect DTF Prints

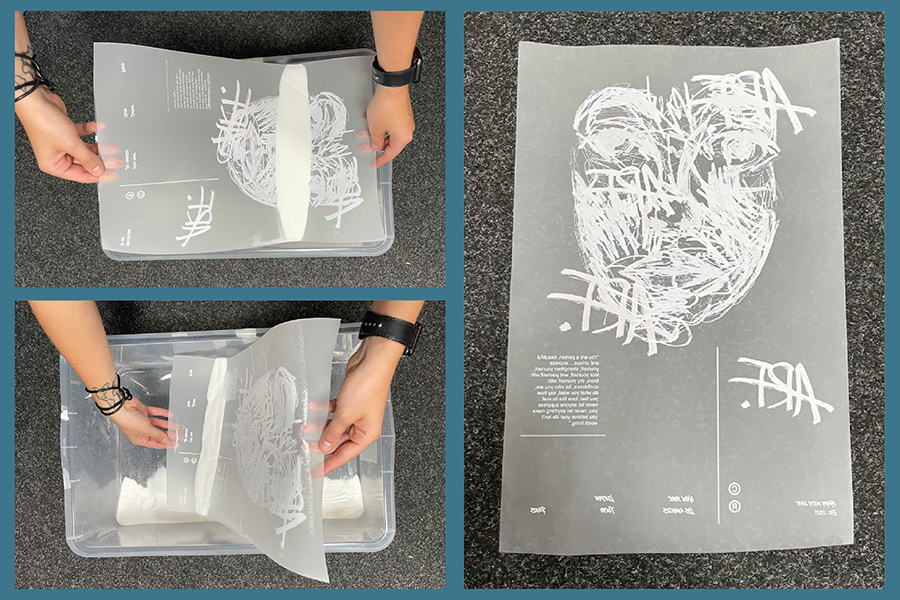

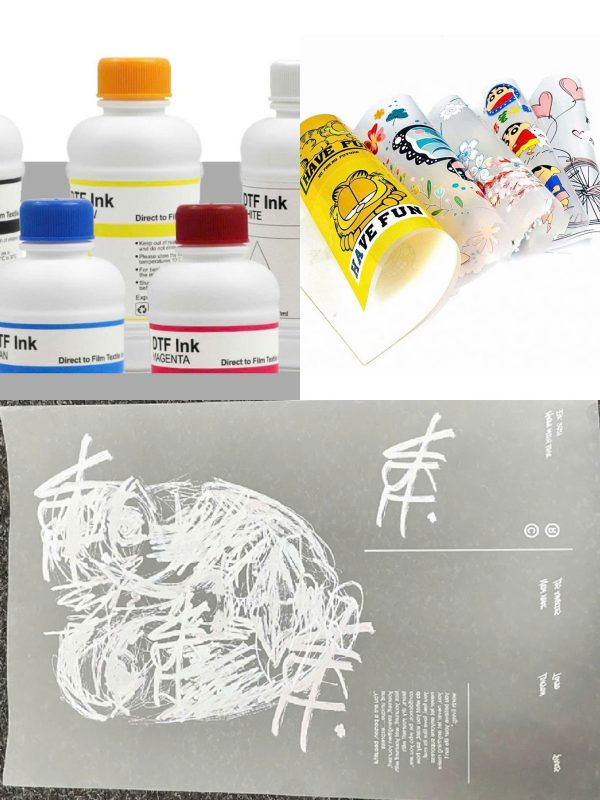

DTF (Direct to Film) Printing Technology has quickly won the hearts of printing workshops due to its incredible versatility. It allows printing onto almost any type of fabric—from cotton and polyester to blended materials—without any complex pre-treatment processes. However, to create a truly perfect, sharp, and durable print, we must focus on two seemingly auxiliary elements that play a decisive role: DTF Film and DTF Powder (Hot Melt Adhesive Powder).

The Film acts as the template where the ink is fixed, while the DTF Powder is the thermal adhesive that forms a permanent “bond” between the print and the fabric fibers. If the selection is incorrect, the print may crack right after the first wash or become too stiff, compromising wearing comfort. This article will serve as a guiding compass to help you make the wisest decisions for your production process.

I. In-depth Analysis of DTF Film: The Impressive “Release” Capability

DTF Film is a polymer material coated with a special ink-receiving chemical layer. The quality of this coating is the most critical factor. It must be good enough to hold the ink during the printing and curing processes, but it must also completely “release” the ink layer from the film base when heat pressing onto the fabric.

DTF Film is classified by its structure and peeling speed:

In production, we often encounter two main film classifications. Regarding structure, the most common type is Single-Sided Print Film, where only one side is treated to receive ink. This type is easy to use and is the standard for most printers.

However, the more important classification is by the peeling method, as this factor directly affects productivity and the softness of the print:

- Hot Peel Film: True to its name, this film allows the operator to peel the film almost immediately after the heat press process is finished (usually after only a few seconds). This option significantly speeds up production, making it ideal for large-volume orders requiring high output. However, it demands extremely stable quality from both the film and the adhesive powder to avoid the print tearing or peeling uncleanly.

- Cold Peel Film: With this type of film, patience is required. The print must cool down completely (for a few minutes) before the film is peeled. Although it slows down the production speed, Cold Peel Film delivers higher sharpness for small details, intricate lines, and most importantly, produces a softer feel (soft hand feel) for the final print. This is the top choice for high-end products or complex designs.

DTF Film Selection Criteria:

When evaluating the film, you first need to consider the Coating Release Quality. The coating must release the ink cleanly.

Next are the Thickness and Flatness of the film. A good DTF film needs to have an appropriate thickness (usually from 75µm to 100µm) and must be perfectly flat to avoid damaging the printhead.

Finally, check the Anti-Static capability. Static electricity will attract dust and adhesive powder debris onto the print, leading to irreparable printing defects.

II. In-depth Analysis of DTF Powder (Thermal Adhesive): The Factor that Creates Durability

DTF Powder, or Hot Melt Adhesive, is the component that creates the bond between the ink and the fabric fibers. It is a polymer that melts at high temperatures and forms a permanent, elastic adhesive layer.

DTF Powder is classified by its particle size and intended use:

- Classification by Micron Size:

Coarse Powder: Large particles, suitable for solid block print designs that require high coverage, but may create a slightly thick and stiff feel on the fabric.

Fine/Super Fine Powder: The ideal powder type for small details and thin lines. Importantly, it provides a soft, elastic, and less noticeable print feel, making it highly suitable for stretchy fabrics like sportswear.

- Classification by Melting Point and Color:

Low-Temp Powder: This powder has a low melting point (often below 130°C), making it the optimal choice for heat-sensitive fabrics such as Nylon, Polyester, or Spandex, helping to prevent scorching or damage to the fabric fibers.

White and Black Powder: White powder is the standard. Black Adhesive is used for dark-colored fabrics, helping to increase contrast and prevent the white color of the adhesive from showing at the print edges.

Optimal DTF Powder Selection Criteria:

- Melting Point: Must be absolutely compatible with the type of fabric you are printing on. This is the decisive factor for avoiding damage to the material and ensuring the adhesive melts properly.

- Elasticity: The powder must have high stretchability. This is a vital criterion for stretchable garments, such as sports t-shirts. Poor quality powder will cause the print to crack immediately when the fabric is stretched.

- Wash Resistance: Always request specifications regarding wash durability. High-grade adhesive powder will ensure the print does not peel off, fade, or change texture after numerous washes.

III. Combining Powder and Film: The Perfect Harmony

The optimal choice is not about selecting the best film or the best powder, but about finding the harmonious combination between them based on the product goals.

1. Soft Hand Feel and Detail

If the goal is for the print to be as soft and unnoticeable as possible, you should prioritize using High-Quality Cold Peel Film combined with Super Fine Powder. Super fine powder creates a thinner, more elastic adhesive layer, helping the print become lighter and integrate better into the fabric.

2. Durability and Adhesion on Difficult Fabrics

When printing on difficult-to-adhere fabrics such as Nylon or water-resistant fabrics, you need to use Low-Temperature Adhesive Powder (to protect the fabric) that also possesses High Adhesion. In this case, Cold Peel Film is often recommended to maximize the pressure force as the print cools down. Always conduct internal wash tests before mass production to determine the actual durability.

3. Productivity Optimization

If you are operating an industrial printing workshop, Hot Peel Film is mandatory. Although the film cost may be higher, the ability to shorten the heat press cycle from a few minutes to a few seconds will help increase productivity many times over, offsetting the material cost.

IV. Solving Common Issues Through Material Selection

Most DTF printing problems can be resolved by adjusting the materials:

- Print Cracking: Highly likely due to the adhesive powder being too stiff or having poor elasticity. Solution: Switch to Super Fine Powder with higher elasticity (often advertised as “highly elastic”).

- Print Peels Uncleanly/Is Faint: Could be due to poor film coating quality (poor release property). Solution: Upgrade to Cold Peel Film from a reputable brand or slightly increase the ink/powder curing time to ensure the ink is completely dry.

- Print is Too Stiff/Thick: The issue lies in using Coarse Powder or applying too much powder during the shaking process. Solution: Switch to Super Fine Powder and recalibrate the powder shaker machine to reduce the amount of adhesive on the print.

- White Glue Edges Showing: Occurs when the adhesive powder spreads beyond the printed area. Solution: Improve the accuracy of the powder shaker machine to remove excess powder, or use Black Powder for dark-colored fabrics.

V. Making Smart Decisions

The choice of DTF Powder and Film is a strategic decision that cannot be based solely on the cheapest price. By understanding the differences between Hot Peel Film and Cold Peel Film, and between Coarse Powder and Super Fine Powder, you can fine-tune your production process to achieve all three goals: high print quality, superior durability, and optimal production speed.

Remember, the quality of the input materials is the foundation for the quality of the print. Always test new materials on the target fabric type before mass production. If you need detailed consultation on reputable suppliers or wish to directly compare the technical specifications of any film or powder type, do not hesitate to contact us!