I. The Hybrid Choice for Capital Optimization

In the modern t-shirt printing race, choosing between DTG (Direct-to-Garment) and DTF (Direct-to-Film) is always a difficult decision. DTG offers premium quality, while DTF provides flexibility and speed. For startups or small-to-medium-sized businesses, investing in two separate machines is often too costly.

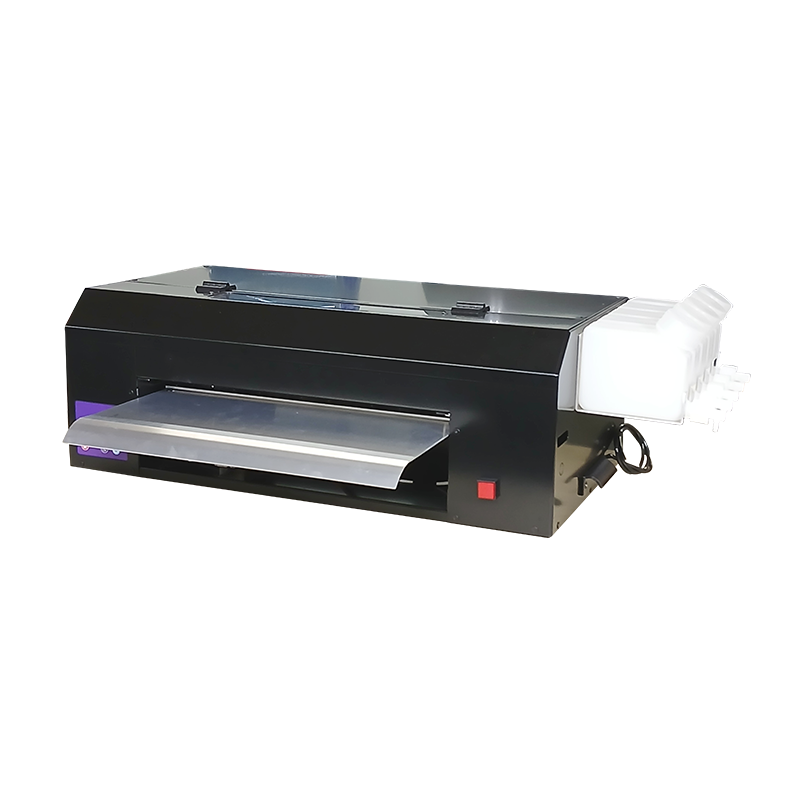

The good news is that the market has introduced Hybrid Printers or conversion kits, allowing a basic DTG printer to perform both functions: Direct-to-Garment printing (DTG) and Direct-to-Film transfer (DTF).

The objective of this article is to deeply analyze the profitability of using this “two-in-one” solution. Together, we will discover 5 profit breakthroughs that this hybrid machine offers, helping you boost efficiency by 300% with just one piece of equipment.

II. 5 Profit Breakthroughs of DTG & DTF “Hybrid” Technology

The Hybrid Solution is not just about convenience; it is a smart business strategy aimed at maximizing the product lifecycle and the target market.

1. Optimizing Initial Investment Costs

A convertible DTG/DTF printer has a significantly lower initial cost than purchasing two separate machines, which helps reduce capital pressure, especially important for startups. Technically, both DTG and DTF utilize similar basic components such as printheads, white ink, and color ink. Sharing these components helps reduce maintenance and material management costs. Consequently, the hybrid solution can help you reduce initial equipment investment costs by 30% to 50% compared to buying both a dedicated DTG and a dedicated DTF system.

2. Market Diversification – Boosting Revenue Scope by 300%

The ability to switch modes helps you serve every customer segment with a single device. When using DTG Mode, you target premium customers, fashion brands, or products printed on 100% Cotton fabric. Profit comes from high pricing (Premium Pricing) due to the soft, high-quality print finish. Conversely, when switching to DTF Mode, you can handle orders requiring speed, or print on challenging materials like Polyester or complex uniforms (Hats, bags). Profit is generated by high volume printing and product diversification. In short, you can print high-end t-shirts for a brand in the morning and sports uniforms (Polyester) in the afternoon, expanding your market reach and multiplying revenue growth.

3. Easy Management – Optimizing Labor & Operational Costs

The hybrid solution reduces the need for specialized labor. Instead of needing one employee to manage DTG and another for DTF, you only need to train staff to master one machine, which cuts labor costs and increases team flexibility. In addition, hybrid printers often use a shared ink type (DTG/DTF Hybrid Ink), simplifying the purchasing process and reducing inventory levels. For maintenance, you only need to take care of one machine. Notably, alternating operation between the two modes can even make the printheads less prone to clogging than using DTG alone, as the white ink is circulated more frequently.

4. Minimizing Error and Waste Rate

Reducing waste directly improves net profit. The biggest advantage of the DTF mode is that you print onto film first. If there is a color error or line defect during printing, you simply discard the film, without ruining the expensive garment (which often happens with direct DTG printing). The ability to inspect the print on the film before pressing is an extremely effective layer of profit protection. Consequently, a business can reduce the waste rate of 100% Cotton garments (expensive material) from 15% down to just 2-3%, significantly increasing net profit.

5. “Print Now – Get Now” Speed – Maximizing Seasonal Profit

The hybrid machine allows you to flexibly maximize profit based on the time of year. When customers need small orders or express printing within 1-2 hours, the DTF mode is the perfect speed solution. During peak seasons like holidays or major events, the demand for t-shirt printing surges. The ability to switch to DTF helps you rapidly process hundreds of film prints, pre-prepare them, and simply heat press when needed, maximizing overall throughput and profit. The DTF mode helps you meet Print On Demand (POD) requirements most efficiently.

III. The “Two-in-One” Strategy for Big Wins

The DTG/DTF hybrid printer is not just a piece of equipment; it is a business strategy that helps you dominate both market segments: premium quality (DTG) and flexible speed (DTF).

Core benefits of the hybrid solution:

First, it helps save capital by reducing initial investment and maintenance costs. Second, it allows market expansion by serving all materials, all orders, and all customers. Finally, it optimizes operations through easy management, reduced material waste, and increased production speed.

Important Note: When choosing a hybrid printer, ensure the conversion system is easy to operate, and the ink is certified to perform effectively in both modes.

Investing in a “Hybrid Machine” is a smart decision that helps you double your profit in the same space, with the same investment, elevating your printing business to a new level. Get ready to boost efficiency by 300% and “make money hand over fist” in this highly potential printing market.