One of the recent breakthroughs is UV DTF printing. In the constantly evolving world of printing, new technologies are continuously emerging to meet the increasing demand for quality, durability, and flexibility. One of the recent breakthroughs, creating a strong wave, is UV DTF printing (Ultraviolet Direct to Film). So, what exactly is this technology, and why is it so highly regarded?

What is UV DTF Printing?

UV DTF stands for Ultraviolet Direct to Film. It is a heat transfer printing method that uses UV ink (ink that dries instantly under ultraviolet light) on a specialized film, and then transfers that image onto the surface of the material to be printed. The distinctive feature of this technology is its ability to print on various hard, uneven, or complex-shaped materials that traditional flatbed UV printing methods struggle with.

UV DTF printing combines the advantages of both UV printing and DTF (Direct to Film) technology, resulting in prints with excellent adhesion, vibrant colors, and high durability.

How UV DTF Printing Works

The UV DTF printing process involves the following main steps:

- Printing onto Film A (Transfer Film): The UV DTF printer directly prints the designed image onto Film A, a special film that already has an adhesive layer. UV ink is sprayed and instantly cured by the integrated UV lamp on the machine, adhering firmly to this adhesive layer.

- Laminating with Film B (Laminating Film): After the image and adhesive layer are printed/present on Film A, a protective film, called Film B (or laminating film), is pressed onto the ink and adhesive layer. This Film B helps protect the image during transportation and storage and ensures the adhesive layer is uniform.

- Cutting and Preparing the Image: The printed image section on Film A, protected by Film B, is cut. When ready to use, the user simply peels off Film B, exposing the image side with the adhesive.

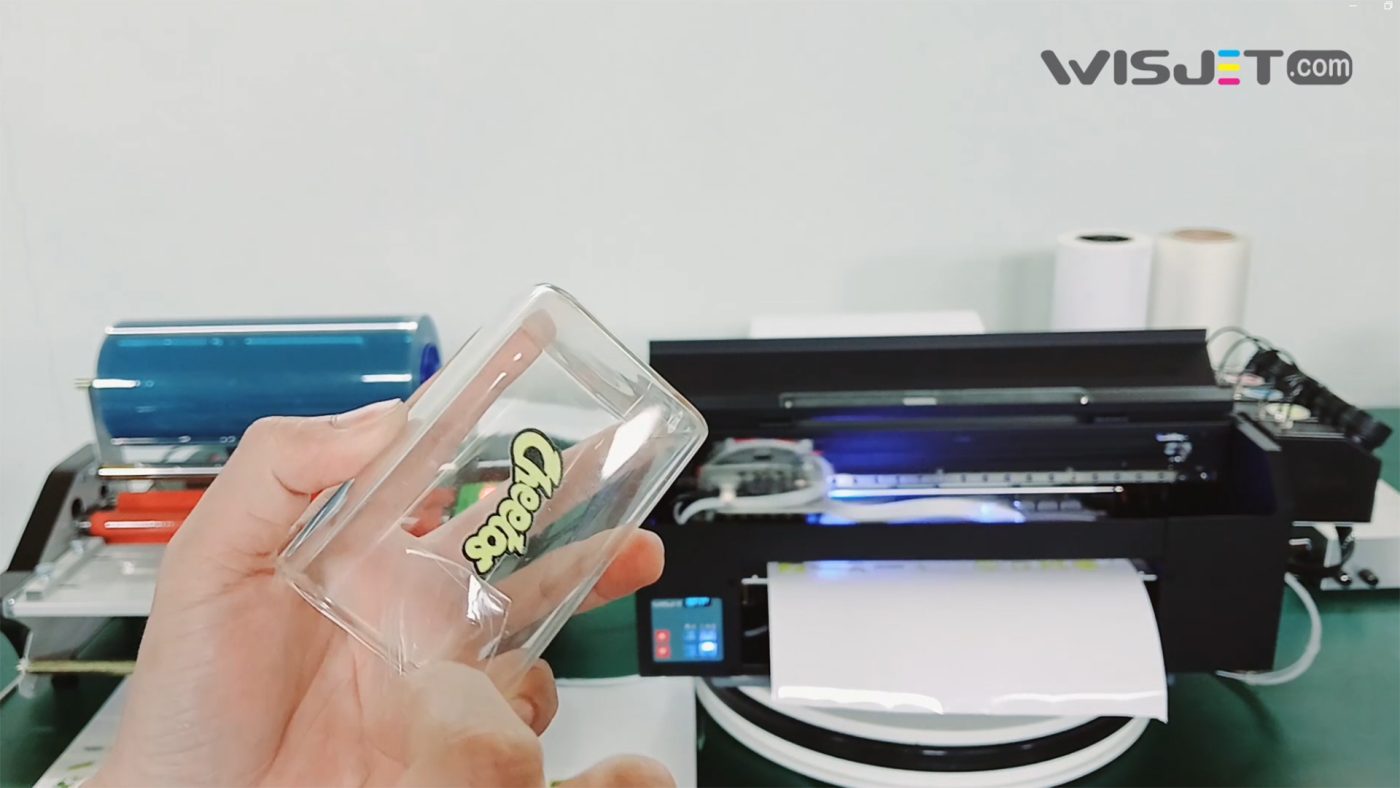

- Applying to Material: The created UV DTF decal is directly applied to the surface of the material to be printed (such as glass, metal, plastic, wood, ceramics, etc.). Then, gently rub with a hand or tool to ensure the image adheres firmly to the surface.

- Peeling off Film A: Finally, gently peel off Film A, leaving the printed and fully adhered image on the product surface. The ink and adhesive layers bond tightly to the material, creating a sharp and durable print.

Outstanding Advantages of UV DTF Printing

UV DTF printing offers many significant benefits, making it an attractive choice for various applications:

- High Flexibility: This is its biggest advantage. UV DTF can print on almost any type of hard, flat, curved, or irregular surface, such as glass, metal, plastic, ceramics, wood, leather, bottles, cups, gift boxes, etc., without the need for complex pre-treatment.

- Superior Durability: Once cured, UV ink boasts excellent resistance to scratches, water, fading from sunlight, and chemicals. Prints maintain their sharpness and vibrant colors for a long time.

- No Surface Pre-treatment Required: Unlike traditional flatbed UV printing, which often requires materials to be coated with a primer or undergo corona treatment, UV DTF eliminates this step, saving time and cost.

- Vibrant Colors and 3D Effects: UV ink allows for vibrant color reproduction and sharp details. Notably, it can create raised or 3D effects by printing multiple layers of ink, providing a realistic and premium feel to the product.

- Time and Effort Savings: The printing and transfer process is simple, fast, and particularly efficient for small orders or personalization.

- Mass Production Capability: With a dedicated printer, a large number of UV DTF decals can be printed in bulk for storage and use as needed, optimizing the production process.

- More Environmentally Friendly: UV ink contains no volatile solvents, minimizing VOC (volatile organic compounds) emissions, making it safer for users and the environment.

Practical Applications of UV DTF Printing

With its outstanding advantages, UV DTF printing is widely applied in many fields:

- Personalized Items and Gifts: Printing logos and personalized images on mugs, thermal bottles, phone cases, notebooks, pens, lighters, USB drives, jewelry, etc.

- Electronics and Devices: Applying labels and specifications on computer casings, headphones, home electronic devices, industrial components.

- Product Packaging: Creating labels and logos on cosmetic bottles, paper boxes, handbags, and premium product packaging, helping to enhance brand recognition.

- Advertising and Decorative Materials: Decals for glass doors, small signs, badges, interior decorative items, etc.

- Fashion Accessories: Printing on metal buckles, bag accessories, shoes, etc.

- Arts and Crafts: Creating unique decorative details for handmade products and models.

Things to Note When Using UV DTF Printing

While offering many advantages, UV DTF printing also has some considerations:

- Initial Cost: Investing in a UV DTF printer and specialized consumables can be higher compared to some traditional printing technologies.

- Operator Skill: To achieve the best print quality and avoid material waste, operators need certain skills and experience.

- Imperfect Surfaces: Although flexible, on overly rough surfaces or those with complex details, the adhesion and detail of the image might be affected.

- Difficulty of Removal: Once applied, UV DTF images are very difficult to remove without damaging the surface or leaving adhesive residue.

Conclusion on UV DTF printing

UV DTF printing is truly a significant advancement in the printing industry, opening up many new possibilities for product personalization and decoration. With its ability to print on diverse materials, high durability, and excellent image quality, this technology is steadily asserting its position, becoming an ideal solution for businesses and individuals seeking differentiation and efficiency in production.