DTF (Direct to Film) printing is a popular heat transfer technology thanks to its sharpness, vibrant colors, and adhesion capability on many fabric types.

However, many users encounter the problem of the transfer cracking or peeling after washing or during use. This quality issue seriously affects product quality and brand reputation.

This article will delve into analyzing the causes of this type of failure and provide effective corrective actions as well as preventive tips so you can create the most durable apparel.

I. Causes of Cracked/Peeling DTF Prints

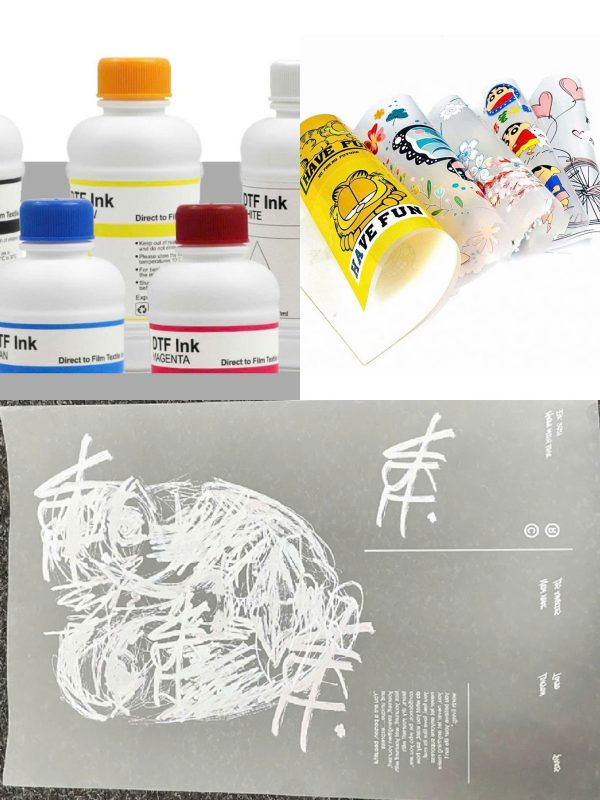

1. Causes Related to Consumables (Ink, DTF Adhesive Powder, Film)

Poor Quality Ink: The ink lacks sufficient flexibility/elasticity, causing the final image to become stiff and prone to cracking when the fabric stretches. Check the expiration date on the packaging if the DTF ink is past its shelf life (DTF ink typically has a shelf life of about 1 year).

Substandard DTF Adhesive Powder (Powder):

- Poor quality glue: Low adhesion, easily peels off. May be expired.

- Insufficient glue quantity: The glue does not cover evenly or is not enough to create a strong bond between the print and the fabric fibers.

- Glue not melted/cured completely: Due to the curing temperature being insufficient or the curing time being too short.

2. Causes Related to the Heat Press Process

Pressing temperature is too low: The adhesive has not been fully “cured” and cannot create a durable bond with the fabric fibers. This leads to the graphic lifting immediately after removing the film or after a few washes.

Insufficient pressing pressure: Not enough force to press the image deeply into the fabric fibers, causing the print to adhere superficially to the surface.

Insufficient pressing time: Similar to temperature, pressing too quickly prevents the glue from being fully activated or adhering deeply.

Peeling the film too early/too late:

- Cold Peel (Peeling when still hot): The glue has not had time to harden, easily damaging the details of the print.

- Hot Peel (Peeling when completely cool): Can be difficult to peel or leave some ink residue on the film.

3. Causes Related to Fabric and Care

Fabric Type: Water-repellent fabrics, oiled fabrics, or fabrics with excessively high elasticity can increase the risk of print damage.

Care and Maintenance:

- Washing with hot water: Causes the adhesive to soften and reduces adhesion.

- Using strong detergents/bleach: Erodes the adhesive and the printed image.

- High-temperature drying: Causes sudden fabric shrinkage, leading to the image cracking.

II. How to Fix and Optimize Quality

1. Control the Quality of Input Consumables

- Use specialized DTF ink: Choose ink with high elasticity (Stretchability). Ensure the consumable is stored properly, away from direct sunlight.

- Select high-quality adhesive powder: Use fine-grain powder with good adhesion (often Type A glue or glue imported from reputable brands).

- Ensure even glue coverage: Use an automatic powder shaker machine or manually check to ensure the powder completely covers the graphic.

- Optimize the powder curing process: Ensure the glue melts and becomes completely transparen (typically at 130ᵒC- 165ᵒC for 90 – 120 seconds).

2. Establish a Standard Heat Press Procedure

Apply the “Golden Heat Press Formula” for DTF:

- Temperature: Usually 150ᵒC – 165ᵒC. Adjust according to fabric and adhesive type.

- Time: 10 – 15 seconds (first press) and 5 seconds (second press, if needed).

- Pressure: Heavy Pressure is mandatory to embed the print deeply into the fabric.

Double Press Procedure – An Advanced Method for Durability:

- 1st Press: Press with standard temperature/time. Peel the film (Hot/Cold) according to the film manufacturer’s instructions.

- 2nd Press (Finishing): Place a layer of parchment paper/non-stick paper over the print and repress for 5 seconds. This helps the design adhere more firmly, smooths the surface, and increases durability.

3. Product Care and Maintenance Guide (Tips for Customers)

- Wait 24 Hours after pressing before washing: This allows the DTF adhesive to reach maximum hardness and bonding strength.

- Wash with cold/warm water: Avoid washing with excessively hot water (below 40ᵒC).

- Wash inside out: Turn the product inside out when washing to reduce direct friction on the print.

- Limit machine drying: If drying, choose a low-heat setting. Air-drying is best.

- Do not iron directly on the print: If ironing is necessary, place a thin cloth layer over the print or iron from the inside-out (reverse side).

III. Comparison with Other Printing Technologies (Increasing Reliability)

- DTF Printing vs. Screen Printing : DTF is more elastic than screen printing but may be less durable if low-quality ink/adhesive is used.

- DTF Printing vs. Vinyl/Decal Printing: DTF does not become stiff/thick like vinyl, reducing the risk of large-area peeling, but it requires a more precise heat press process.

The phenomenon of cracking/peeling is not an inherent flaw of the technology but primarily stems from failure to adhere to the standard procedure and the use of substandard consumables.

You should invest in high-quality DTF printing supplies and, especially, strictly control the heat press process (Temperature, Pressure, Time) to ensure your finished goods can last up to hundreds of washes.

If you encounter any issues during the printing process, please contact our experts for detailed consultation and to receive the complete standard heat press formula set.