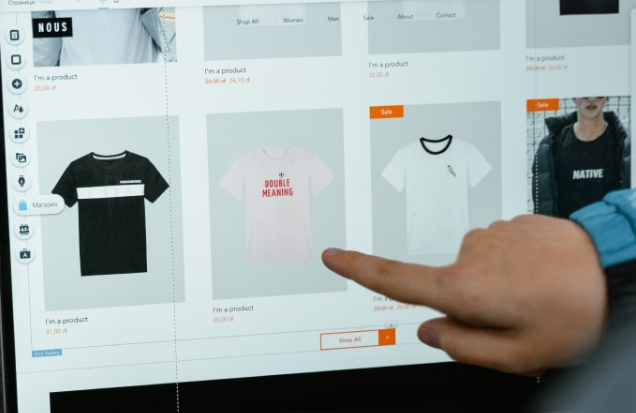

Do you have a unique design idea but are hesitant about production costs and the fear of inventory? Print on Demand (POD) is exactly the solution you’ve been looking for. This is not just a business model; it’s a revolution for creators, allowing you to turn ideas into actual products without worrying about stock or initial capital investment.

How Does POD Work? Surprisingly Simple!

Instead of mass production, POD operates on the ‘print-when-ordered’ principle. The process is incredibly simple:

- You Create the Design: Whether it’s a photo, a quote, or a hand-drawn illustration, you simply upload the design to the POD platform.

- The Customer Places an Order: Once an order is placed, the system automatically sends a request to the printing facility.

- Printing, Packaging, and Shipping: The POD service provider handles all the remaining steps, from printing and careful packaging to delivering the product directly to the customer.

You completely avoid the need to hold inventory or worry about the shipping phase. Everything is automated.

In Which Fields Is POD Applied?

“POD is not limited to just T-shirts. It’s a vast universe with countless opportunities:

- Fashion and Apparel: Diverse items from T-shirts, hoodies, and hats, to canvas tote bags. This is the most common starting field for newcomers.

- Home Goods and Decor: Transform familiar items like ceramic mugs, throw pillows, wall art, or even bed sheets and duvet covers into unique works of art.

- Accessories and Electronics: You can design phone cases, mouse pads, or laptop sleeves with a distinctive style.

- Books and Stationery: This model helps authors self-publish books without worrying about volume. Additionally, you can sell exclusive notebooks, calendars, or greeting cards.

- Even Footwear and Jewelry: Although more complex, POD has also expanded into these highly personalized, high-end items.

Why Should You Try Print on Demand (POD)?

Zero Risk: You do not need to invest a large amount of capital to produce inventory, completely eliminating the risk of unsold stock.

Creative Freedom: You can experiment with dozens, even hundreds of different designs without worrying about production costs.

Time Savings: Focus entirely on building your brand, creating content, and connecting with customers. All logistical stages are handled by the POD partner.

Suitable for All Audiences: Whether you are an artist, an influencer, or simply someone who wants to try their hand at business, POD is an ideal choice.

Home-Based Print on Demand (POD) Production Model

Without needing a large investment, you can still build a Print-on-Demand (POD) production model right at home. With this approach, you fully control the process, making it easy to tightly manage product quality. Furthermore, taking the initiative in production allows you to quickly fulfill all orders and meet diverse customer demands, creating a superior competitive advantage.

Fashion and Apparel Model

Are you looking to enter the fashion market with unique printed products? The at-home fashion and apparel printing model is an ideal choice. With a DTF (Direct-to-Film) printer and accompanying equipment, a digital printer allows everyone to create with ease, simplicity, fabric efficiency, consistency, and most importantly, color diversity on fabric, making the entire process reliable and cost-effective. You can easily create high-quality products such as T-shirts, tote bags, hats, and more.

What You Need to Start:

- DTF Printer: This is the “heart” of this model, allowing direct printing onto a film/foil—the latest inkjet printing method, which uses inkjet technology to print images onto specialized film. These images are then transferred onto the fabric with vibrant colors and high durability.

- DTF Adhesive Powder: The hot-melt adhesive powder is coated onto the image after printing. Under the action of heat, this powder layer melts and creates a strong bond between the print and the material.

- DTF Ink: Includes basic color inks (CMYK), white ink, and potentially fluorescent inks. The white ink serves as a foundation, allowing printing on dark-colored fabrics as well.

- DTF PET Film: This is the specialized film used to print the image onto before heat transfer.

The DTF printer does not require users to invest heavily. Users only need to invest in a few items such as film, ink, hot-melt powder, software, and the printer. With just this equipment, you can create a complete POD production process yourself, being proactive from the design stage to the final product.

POD Printing Model with a UV Printer

If you want to expand your product offerings to hard materials, the POD printing model using a UV printer is the perfect choice. UV printing technology allows direct printing onto almost any surface, from wood, glass, metal, plastic, and leather, to phone cases and computer covers.

Outstanding Advantages:

- Material Versatility: Not limited to fabric, you can print on many different materials, expanding your product catalog.

- Sharp, Durable Images: UV ink dries instantly thanks to UV lamps, creating images with high durability, good scratch resistance, and water resistance.

- Create Unique Effects: It is possible to print white ink and varnish ink to create embossed, glossy, and other unique effects on the product.

With a UV printer, you can create high-end personalized products, from artwork and decorations to gifts, meeting the tastes of customers who appreciate uniqueness.

Other Potential POD Production Models

In addition to the two models above, you can explore many other options to diversify your products:

- Direct to Garment (DTG) Printing: Prints directly onto fabric, suitable for cotton, resulting in detailed and sharp images. However, the cost is high, it is only optimized for small quantity orders, and requires pre-treatment of the fabric before printing.

- Screen Printing: Suitable for large quantities, low cost, and durable prints. However, the process is manual, slow, and not suitable for complex designs or printing small quantities.

- Dye-sublimation Printing: Provides bright colors, with the print sinking into the fabric. The disadvantage is that it can only be printed on white or light-colored polyester fabric.