What is DTF and DTF Printing Technology—A New Era for the Printing Industry As traditional printing technologies like heat transfer and screen printing gradually reveal limitations in terms of material versatility, image quality, or production time, the printing industry is welcoming a powerful new wave: DTF (Direct to Film) Printing Technology.

So, what is DTF that allows it to create such a revolution in the printing field?

What is DTF?

DTF (Direct to Film) is a printing process where an image is printed directly onto a special film (transfer film). After being coated with adhesive powder and cured (dried), the image forms a complete “transfer sticker” (or “transfer”).

Finally, this “transfer” is heat-pressed onto the material to transfer the entire image and adhesive layer onto the substrate.

DTF Comparison with Other Technologies

DTF significantly outperforms other printing technologies in several key aspects:

- DTF vs. Heat Transfer Printing: Heat transfer is often only effective on light-colored polyester fabrics. In contrast, DTF printing can be used on all types of fabrics, from cotton, polyester to blended materials, and is particularly effective on dark-colored fabrics. DTF colors are also more vibrant, realistic, and have superior durability.

- DTF vs. Screen Printing: Screen printing requires making a separate screen (stencil) for each color, which consumes time and cost for small-quantity orders or complex designs. With DTF, you only need the design file to print directly, eliminating the need for screens, which saves significant cost and time, making it particularly suitable for on-demand printing.

- DTF vs. DTG (Direct to Garment): Although DTG is a modern digital printing technology, DTF still proves superior in terms of flexibility. DTG is often material-sensitive and yields the best results primarily on cotton fabrics. Meanwhile, DTF can print on any material, thereby significantly expanding its range of applications. Furthermore, DTF offers greater durability and is more cost-optimized for both small and large print quantities, making it a more comprehensive and efficient choice.

The DTF Printing Process

The DTF printing process is quite simple and easy to execute:

- Design: You only need to prepare the design file on a computer using professional graphic design software.

- Direct Printing onto the Film: The design file is printed directly onto the PET film using a DTF printer. Note that the image must be printed in reverse (mirror image) so that when it is pressed onto the material, the image will face the correct direction.

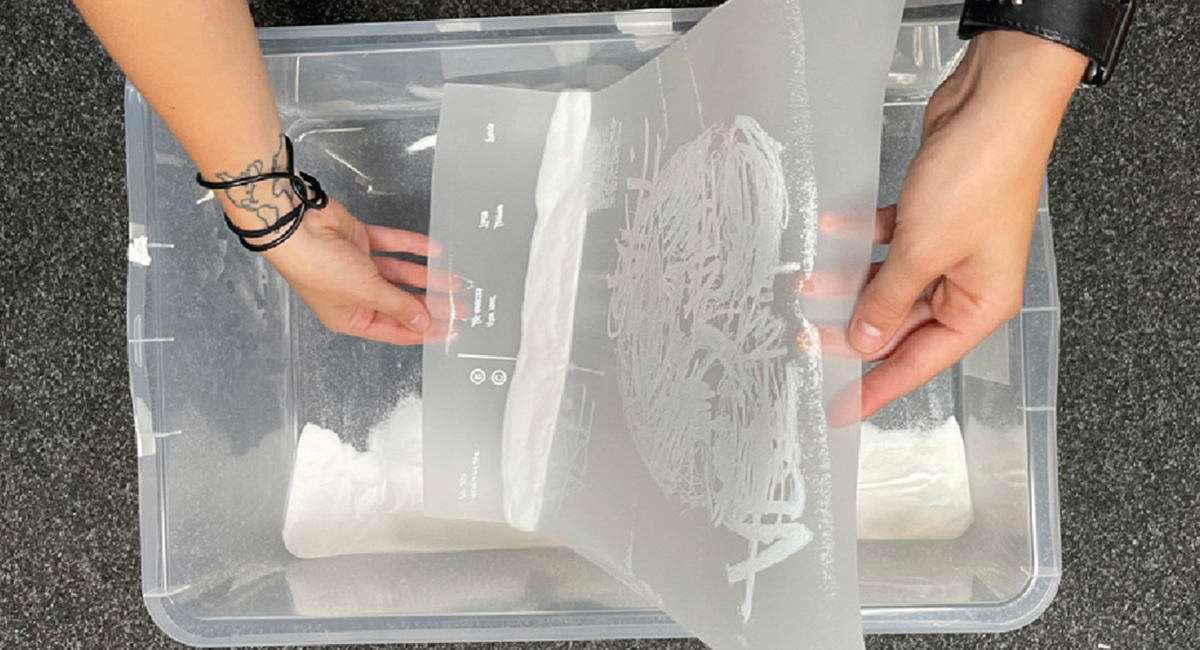

Applying Adhesive Powder and Curing: Immediately after printing, the film is coated with a layer of hot-melt adhesive powder. It is then cured (dried) using heat to ensure the adhesive melts and securely bonds with the ink

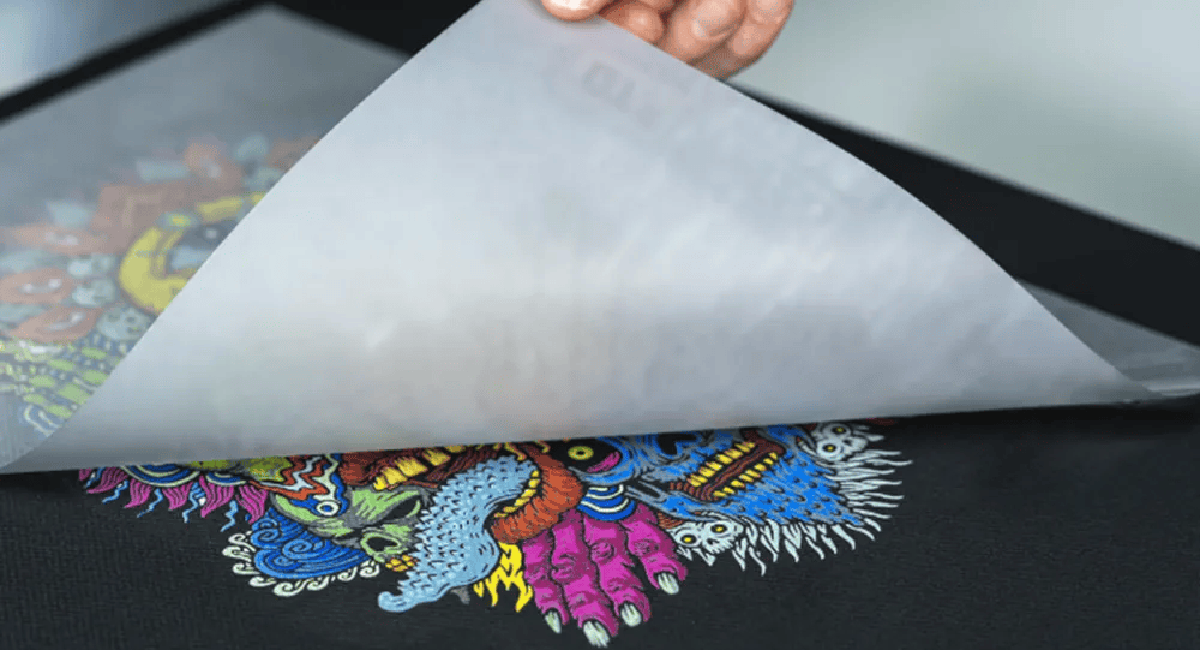

Heat Pressing onto the Material: Place the prepared film onto the target material (substrate) and use a heat press machine to transfer the image. After pressing, peel off the film layer, and the image will be securely adhered to the material.

Outstanding Applications of DTF Printing Technology

DTF printing technology is applied across a wide range of fields:

- Fashion & Apparel: From printing on T-shirts, corporate uniforms, team wear, to bags and fashion accessories. DTF allows complex, multi-colored designs to be vividly rendered on all types of fabric.

- Gifts & Personalized Products (POD – Print On Demand): DTF is the ideal solution for printing logos, images, and messages onto custom products such as hats, backpacks, face masks, and various other souvenirs.

- Specialty & Difficult Surfaces: This technology extends printing capabilities to surfaces where traditional methods struggle, including leather, wood, glass, and metal (often utilizing UV DTF printing), significantly diversifying the product catalog.

With its outstanding features and easy printing process, DTF technology is steadily asserting itself as a comprehensive, flexible, and efficient printing solution. Thanks to its versatile material compatibility, sharp image quality, and simple procedure, DTF not only helps businesses optimize production but also opens up endless creative possibilities for designers and printing professionals.